Erosion by UV and High-Speed Rain Impact Damages at Different Blade Locations to Causes Stress Concentration and Unforeseen Catastrophic Failure. Ability to monitor the rate of erosion and vibrational abnormality may preventive maintenance and timely repairs when needed.

Micromonitor™ Erosion and Corrosion Rate Monitoring Systems is Part of the holistic AVANTE Wind Turbine Integrity Monitoring System (WTIMS) for Monitoring Erosion and Corrosion Thinning of Rotor Blade and Steel Structures

Leading edge effect (LEE) of the wind turbine blade (WTB) erosion is one of the main causes of wind turbine mechanical failure and slow degradation of the wind energy conversion efficiency. It is one of the major costs in the operation for inspection, repair and maintenance. AVANTE MICROMONITOR erosion rate monitoring system can provide predictive maintenance scheduling without onsite inspection.

With unforeseen build-up of the stress concentration at some weak point of the rotor blade, the initiation of fracture not only can cause catastrophic breakdown of the rotor blade, it can also lead to the destruction of the windmill structure. AVANTE MICROMONITOR™ sensor system can provide rate of degradation for predictive maintenance without human onsite inspection.

Digitization of Erosion Rate:

Inspection by human and intelligent drone can only done periodically and qualitatively. The rate of erosion of rotor blade is initiated by UV exposure and increasing rate with surface degradation and thus are unlikely to be linear in rate over time. Thus, a suitable duration between inspection may be difficult to gauge. On top of the fact that human judgement is often unsatisfactory for prediction of potential for catastrophic failures.

Digitization of Corrosion Rate:

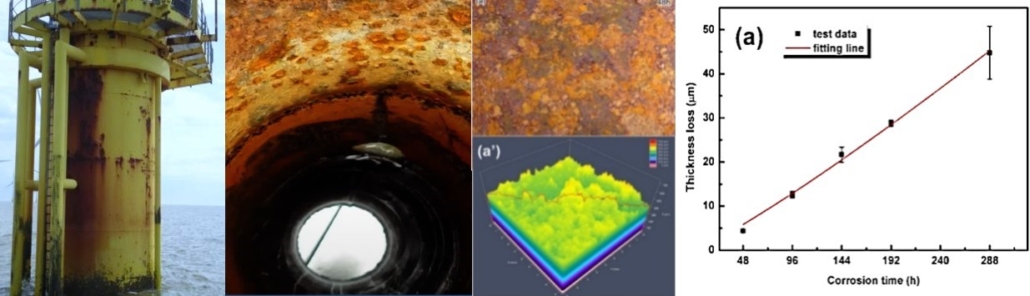

Similarly for corrosion of steel structure above and below seawater line and particularly those around the splash zone have dramatically different rate. It is the slow thinning and the RATE OF THINNING caused by corrosion to provide the predictive capability for replacement of remedial actions. AVANTE pipeline thickness monitoring system is used for corrosion thinning of the turbine support structure even without knowing the original wall thickness. Typical accuracy or resolution depends on the overall thickness and are in most cases better than 0.01mm.

Digitization of Factors that Affect the Erosion and Corrosion Rate:

- Erosion rate is determined by the cumulative rain intensity over time and ability to provide quantitative data helps to predict the rate of erosion.

- Corrosion rate is different at the splash zone and immediately above and below the seawater line.

Digitization of Mechanical Responses Help to Provide Timely Repair Before Catastrophic Failures:

- Online and real-time monitoring of the vibration spectral response provides exception real-time alerts.

- Online and real-time monitoring of the stress induced strain exception provides possibility for timely repairs

Corrosion of steel monopile and support structure eat away the steel structure and weakening the support structure. With unforeseen build-up of the stress concentration at some weak point of the steel support, the initiation of fracture not only can cause catastrophic breakdown of the structure. AVANTE MICROMONITOR™ sensor system can provide rate of degradation for predictive maintenance without human onsite inspection.

Online steel thickness measurement overtime provides corrosion rate data for predictive maintenance scheduling before catastrophic failure.