Leakage of lubricant and transmission fluid can affect the wind turbine efficiency and potential mechanical failure. Excessive leakage can also cause contamination around the turbine and also known to cause fire hazard and total system damage.

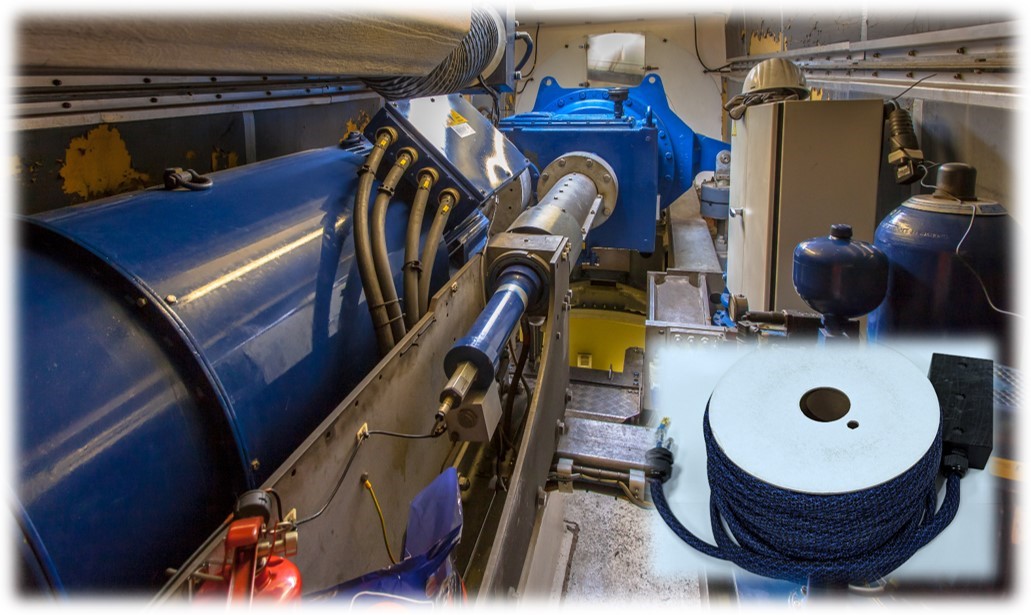

AVANTE Leakage ELECTROSENSOR ™monitoring system for small leakage detection and alert for wind turbine nacelle box is designed engineered to provide false alarm free direct detection of even smallest lubricant and transmission fluid leak around the generator gear boxes within 10 minutes of contact with sensor cable.

AVANTE Leakage ELECTROSENSOR ™monitoring system is engineered to provide false alarm free direct detection of even smallest leak within 10 minutes of contact with sensor cable over the perimeter of turbine generator.

- Leak detection sensor lined around the gear-box and engine where leaks of transmission fluid and lubricant oil can be detected with minutes

- Lubricant oil and transmission fluid leaks can be distinguished to provide times for specific maintenance before disastrous mishaps

ELECTROSENSOR™ sensor cable is used to line around gear boxes containing lubricant and transmission fluids. When any of the flammable fluid leaks and get in contact with the sensor cable can be detected within 10 minutes or longer depending on the types of fluid. Alert is generated automatically and transmitted to responsible management for possible corrective action in preventing contamination and/or fire hazard.