The complete digital inspection tool designed for rail tracks to monitor operational conditions:

AVANTE’s patent-pending Track Integrity Monitoring System (TIMS) is designed to work in conjunction with AVANTE’s Autonomous Track Geometry Measurement System (ATGMS) to provide a real-time and real-live digital inspection of the rail track 24/7/365 while the trains are running on the track. The systems are designed to mount on each side of the engine body to directly image the rail track in real-time. AVANTE’s TIMS incorporates the following technologies to achieve rail track integrity monitoring and defect detections:

The illustration above shows common track defects that gradually get worse, eventually causing train derailment.

Each type of defect and the degree of damage is reflected in the train movements if we monitor them with AVANTE’s Track Integrity Monitoring System (TIMS).

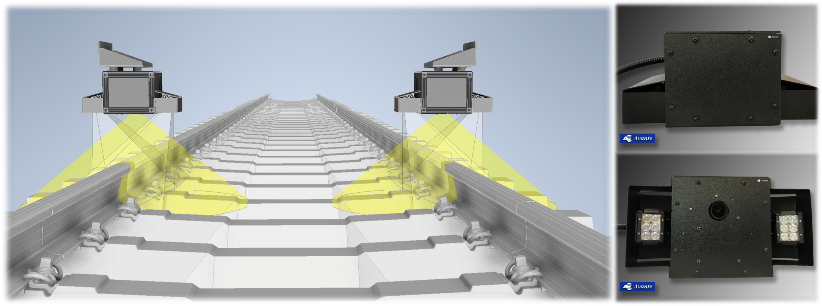

High speed and high-resolution imaging cameras capture the images of the rail tracks, fasteners, and tie-bar that hold the stock rails in place. Sensors within the TIMS (Track Integrity Monitoring System) measure shock, tilt-canting, and vibration experienced by the wheel on each side of the train engine. These sensors provide additional confirmation and more detailed data to the same measurements made by the sensors located in AVANTE’s ATGMS unit. Data is communicated in real-time for out-of-spec exception while all other data will be stored for trend and rate of change assessment. The system uses artificial intelligence (AI) to assess defects from the high-resolution images of the tracks during the train operation.

TIMS (Track Integrity Monitoring System) –

Designed to mount underneath the train locomotive to monitor both tracks and their fasteners in real-time

AVANTE TIMS provides the geo-tagged high-resolution images of the track and the fasteners on the tie-bar to facilitate real-time examination of the track defect exceptions

AVANTE TIMS also operates off-line to provide AI image-based track defect detection with the “known-good-track”. The system highlights any observable deviations to provide monitoring and documentation of all track defects

Detecting Rail Defects

AVANTE’s ATGMS measures the quantitative gauge, tilt, canting, shock-vibration, and temperature of the track every time a train runs on a specific track. Track gauge widening may be caused by a variety of rail track defects. The real-time geotagged images from AVANTE’s TIMS help to provide the virtual onsite inspection without actually traveling to the locations. Broken or missing fasteners on the track are the typical causes of issues. AVANTE’s ATGMS’s real-time and real-live data can be coupled with the real-time imaging data from TIMS to provide powerful preventative maintenance before accidents.

- While broken track can be detected quantitatively with the AVANTE IMU sensor embedded with the AVANTE’s ATGMS, AVANTE Track Integrity Monitoring System (TIMS) geo-tags the nature of the defects with real-time high resolution and high speed image.

- AVANTE’s ATGMS incorporated the IMU sensor to document the excessive shock-vibration while the train is moving on the defective train track surfaces.

- AVANTE’s TIMS geo-tags the full track images and highlight those sections that exhibit excessive vibration-shock and other defects.

- AVANTE’s TIMS also uses AI to compare the previously undamaged track to the images and conditions of the actual track to provide additional capability in predictive maintenance management.

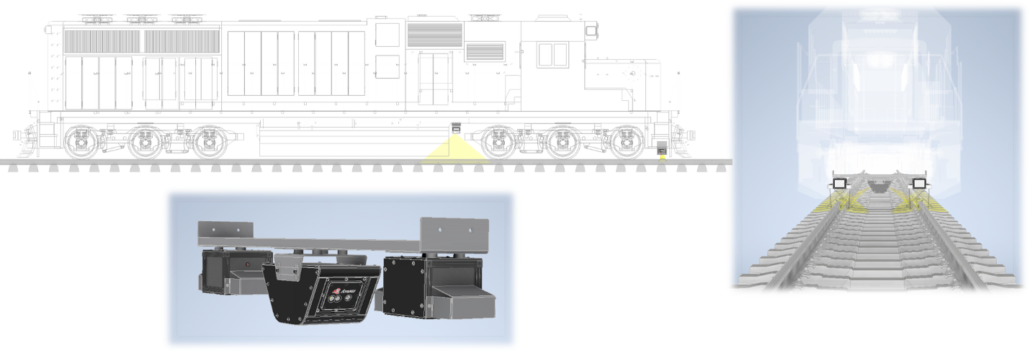

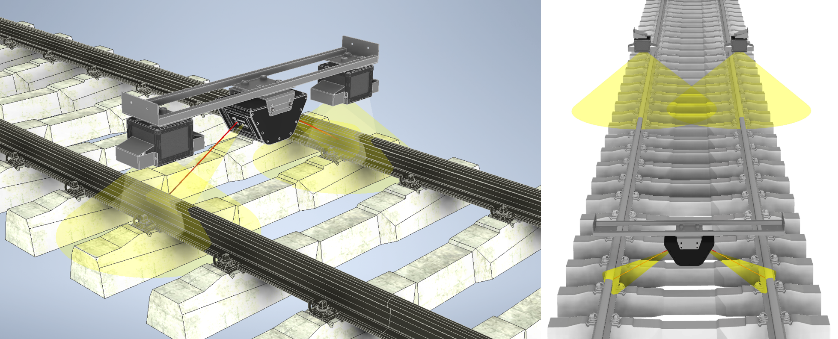

Locating and Mounting the AVANTE’s TIMS and ATGMS:

The above illustrations represent the configuration and installation of ATGMS and TIMS. They can be located adjacent to each other or apart from each other. The geo-tagged track gauge and other data and the high-resolution images help to align the data with the images.

While AVANTE Track Integrity Monitoring System (TIMS) is complementary to the AVANTE ATGMS to provide a more complete picture of the rail track condition for train operation. TIMS can also operate independently without ATGMS.

- ATGMS and TIMS can operate adjacent to each other as illustrated in the configuration on the left.

- TIMS can also operate separately under different positon on the train engine as illustrated on the right.

TIMS and ATGMS

- Both AVANTE’s ATGMS and TIMS are in IP-67 waterproof sealed enclosures.

- The optical-laser components are protected with glass for ease in cleaning.

- Geo-tagged exception data are communicated in real-time.

Using AVANTE’s Track Integrity Monitoring System (TIMS) and AVANTE’s Autonomous Track Geometry Measurement System (ATGMS) to Improve Freight and Passenger Transport Safety and Efficiency:

- AVANTE’s Track Integrity Monitoring System is best working in conjunction with the Autonomous Track Geometry Measurement System designed to mount onto the train engines to measure, image monitor, and communicate geo-tagged exception data in real-time for actionable corrections whenever needed and for providing trend and rate of change for timely maintenance.

- Real-Time reporting of exceptions for emergency repairs and trend of track degradation allows for timely preventive maintenance are keys for safe and efficient rail freight and passenger transport.