High Temperature RFID Tags For Metals and Liquids

Robust and Reliable RFID UHF Tags for Tracking Metal Parts and Parts Containing Liquids or Direct Immersion in Liquid for High Temperature and Conventional Operating Environments

AVANTE incorporates the high temperature stable RFID tags with direct soldered inlays with chips based on UHF ISO 18000-6C EPC Generation 2 protocol into specialty metal and liquid compatible tags for direct attachment on metal parts and containers of liquids. Three different form-factors are available with thicknesses of less than 0.25 inches. AVANTE also offers the industry the first EPC Generation 2 UHF RFID tags for direct attachment on metal parts for tracking and inventory applications that can withstand high temperatures for up to 250 °C of continuous applications. Ideal for manufacturing and extreme operational environments, these high temperature applicable RFID metal compatible tags are made with a patented molecularly flexible high temperature substrate and robust strap and components with wire-bonded chip and soldered interconnections to the RFID antennae.

TAGGING AND TRACKING METAL PARTS AND INVENTORY:

For an effective read distance of large metal parts, AVANTE metal compatible RFID tags based on EPC generation 2 protocol can be read as far as 10-20 ft when directly tagged onto metal surfaces. Metal compatible AVANTE RFID tags are available for standard operations below 80C. AVANTE also offers a high temperature metal compatible RFID that can withstand 250°C continuously. Both the standard and high temperature RFID tags are also functional at low temperatures of below minus 50°C.

TAGGING AND TRACKING CONTAINERS OF LIQUIDS:

![]()

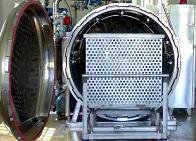

TRACKING PROCESSING OF PARTS IN HIGH TEMPERATURE OPERATIONS:

![]()

For manufacturing operations that must include in-process monitoring, AVANTE high temperature metal compatible tags have proven to be invaluable for such harsh working environments. The parts tagged can be continuously monitored during the high temperature processing.

AVANTE RFID tags are made for extreme applications by incorporating wired-bonded strap module and soldered strap onto RFID tag antennae that are protected with encapsulation from high temperatures and stress in special baking, heat-treating and other industrial processes.