Rail Yard, Wagon Booking-Shunting, Cargo Loading-Unloading, Locomotive-Wagon Maintenance, Crew and Train Scheduling

AVANTE Web-Based Rail Operation Management Module includes all of the operational aspects of rail system with its web-based platform and web service interfacing with any existing legacy database systems. It is scalable for use with low volume rail system with unparalleled cost-effectiveness, and high volume rail operations with complex scheduling.

AVANTE developed and adopted extensive sensor technologies that can be used with the existing and older models of locomotives and wagons or enhanced the functioning of the overall rail operation using a combination of advanced electronics and web-based software. The user friendly yet powerful web-based interface allows for concurrent reporting to authorized stakeholders anywhere in the world.

- Train scheduling based on cargo destination and all existing train schedules

- Real-time visibility of rolling stock availability

- Real-time visibility of crew availability for assignment

- Real-time locating and status of locomotive, fuel, cargoes, wagon decoupling

- Block-based speed tracking for safe and efficient operation

- End-to-end transit history and “play-back” of all operations for credible audit

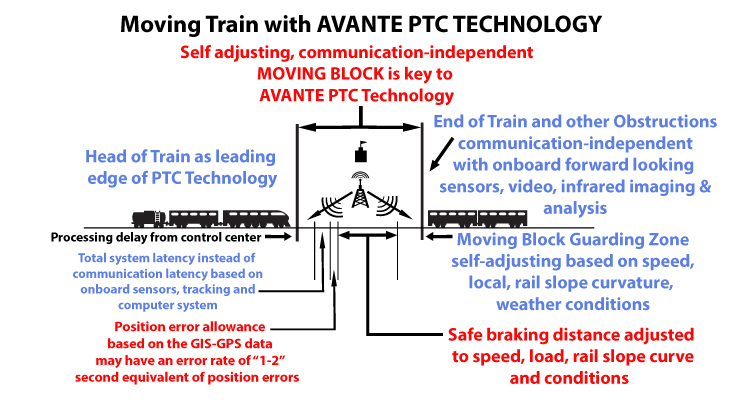

Instead of depending on land-based communication system to provide the relaying of information from one train to the next, AVANTE added onboard communication capabilities to provide visibility of trains on the same track and rail workers working near the track. With the GPS and geo-tagged block specific speed limit, AVANTE RELAYER-CONTROLLER provides real-time alert with the onboard computer for any operational exceptions and automatic control engagement if the train engineer fails to act upon the alerts that require corrective actions.

Customizable Alerts

Alerts are sent via text message, email or phone. Alerts are real-time rather than post-mortem.

AVANTE RELAYER-CONTROLLER is an integrated system with communication capabilities via GPRS-Satellite infrastructure and onboard RF and WiFi communication modems for bi-directional communication between trains on the same track. Real-time visual and sound alerts is provided to the engineers when the speed limit is exceeded based on geo-location of the track, fuel shortage, wagon decoupling and other exceptions. Special alerts are also provided whenever there are rail workers working in nearby track and train in front and behind that are approaching proximity limits.

System Configurations with AVANTE Sensor Devices and Communication Module:

AVANTE Web-Based Rail Operation Management Module provides the real-time visibility of cargo and train for its location and status including speed, fuel level, and fuel efficiency.

RELAYER™-CONTROLLER with Multiple Sensors and Communication Module:

- Supplementing any existing legacy system with today’s most advanced technologies

- GPS for and real-time locating reporting via cellular and satellite data communication

AVANTE RELAYER-CONTROLLER is engineered to retrofit and upgrade any legacy locomotives with GPS-GPRS-Satellite real-time visibility to the central monitoring center and role-based access to some of the stakeholders for different aspects of the data. It also interfaces with the various RFID-based sensors that provides the intrusion detection, temperature-humidity, vibration-shock, rail track integrity monitoring devices and digital fuel sensors for the operation management. Additional module is available for cellular-satellite voice communications with visual displays. Bi-directional communications with trains on the same track is incorporated as part of the positive train control (PTC) system are achieved via long-range RF and WiFi communication platform. AVANTE RELAYER-CONTROLLER unit can also provide automatic or remote controlling of the speed of the train in case of emergency.

End-of-Train Device (ETD) for Real-Time Decoupling and Exception Reporting:

- ETD with RF communication to the RELAYER for real-time reporting of separation of wagon

- Made to enable covert installation

AVANTE ETD is an RFID sensor based device that communicate with the RELAYER-CONTROLLER as to its proximity to the locomotive to provide real-time alert in case of physical separation or decoupling. AVANTE ETD can be installed covertly for optimum security.

Supplemental Digital Fuel Sensor for Real-Time Fuel Level and Usage Reporting:

- Custom installed digital fuel sensors linking to the AVANTE RELAYER™ reporting system

- Direct and real-time alerts for shortage or other exceptions

AVANTE digital fuel sensors directly interfaces with the AVANTE RELAYER-CONTROLLER and report the fuel level data in real-time to the central control center. This cost-effective sensors are used to retrofit any legacy locomotive or as a supplement to even the later models.

Automatic Equipment Identifier(AEI) and/or ZONER™-Tag for Rolling Stock & Train Management:

- Independent and automatic confirmation of wagon shunting sequence in a train

- Automatic documentation and station reporting

AVANTE AEI uses industry standard UHF passive technology while also provides the optional active RFID technology to enhance the visibility as to its location and with optional covert installation to provide theft and tampering monitoring.

Sensor-based AVANTE Track Integrity Monitoring Device for geo-tagging any defective segments of the rail track all while train normal operations:

AVANTE engineered a specialized Track Integrity Monitor that directly interfaces with the RELAYER-CONTROLLER for detailed and complete geo-tagged track condition data based on shock experienced by the train on the track. Maintenance and repair ticket can be generated automatically for timely corrective action before major incidents.

The ability to document the train running conditions on the rail track and geo-tagged any disruptive condition, one can effectively used condition-based maintenance method to the track. This cost-effective automatic AVANTE Track Integrity Monitoring Devices helps to reduce fruitless over-maintenance and thereby ensuring optimal levels of efficiency. As maintenance effectiveness increases, reliability and safety of transport increase, all while achieving a decrease in the overall maintenance costs.