Positive Train Control Via Multi-modal Communication and Intelligent Rail Sensor Network

According to the 2010 GAO report (http://www.gao.gov/new.items/d11133.pdf ), for the last 10 years of the rail accidents, 35% are attributable to human factors, while 32% are attributable to rail track defects and 12% to equipment failure, 7% rail crossing, 2% being signal problem and 13% attributable to other causes. With the currently mandated Positive Train Control solution, it can only address 30% of the causes of rail accidents. AVANTE Rail Safety Technologies and Solutions have been designed to address most of the other causes of rail accidents while also provide supplemental benefits to the PTC solutions being implemented.

Accurate 24/7/365 monitoring of the rail track condition and reporting will dramatically improve the allows true preventive maintenance and lower the needs of the current costly reactive maintenance. The current and commonly used periodic inspection methodologies are only as good as the system’s capability and the inspectors that are carrying out the inspection. These inspection methods and protocols are not known for its reliability or cost effectiveness.

Both reactive maintenance and the periodic inspection protocols cannot help to prevent accidents that are caused by the rail track distortion and other issues that happens between inspections.

A real-time reporting of rail track integrity issues that may cause accident to the rail infrastructure management is good only if the problem can be fixed in time before a train passing through them.

AVANTE Rail Gauge and Rail Integrity Monitoring System is designed to provides a cost effective technologies and devices located along the rail track to provide 24/7/365 reporting of the exact condition of the track in terms of gauge distortion and support structure erosion and damages. The exceptions that may cause a train accident are reported in real-time to the monitoring control center as well as broadcasted to the on coming trains that will be using the track to allow the train engineer to stop or slow down to avoid the potential hazard. AVANTE believes this advanced patent-pending solution will help to substantially reduces the known 32% of the train accidents that are attributed to the rail track defects.

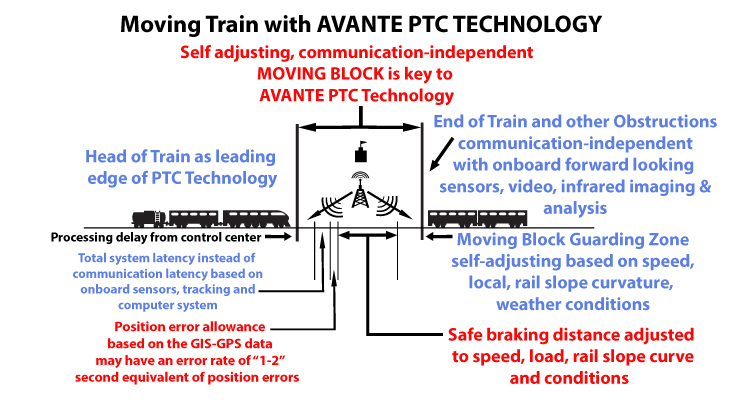

AVANTE incorporated a series of advanced technologies in a comprehensive solution in creating safety “envelope”, or “moving block system or communication based control system” that provides visibility and moves with the train in meeting the basic mandates of Positive Train Control (PTC):

AVANTE incorporated a series of advanced technologies in a comprehensive solution in creating safety “envelope”, or “moving block system or communication based control system” that provides visibility and moves with the train in meeting the basic mandates of Positive Train Control (PTC):

1. Prevention of train-to-train collisions:

- Real-time location and onboard display of all trains in the train line and block of interest to the train engineers within the block.

- AVANTE active RFID based ETD and AEI to provide immediate alert between the trains whenever they are within the range of 1000 meter.

- The combination of technologies supplement the central train scheduling control with positive confirmation for proper train separation and collision avoidance.

2. Over-speed protection, and enforcement of civil speed restrictions

- Each of the rail line block is individually geo-tagged with block-specific speed limit that are monitored by both onboard AVANTER RELAYER-CONTROLLER.

- Automatic activation of braking system to slow or stop the train after a defined period of buzzer alerts to the train engineer driver to provide a positive line speed enforcement.

3. Detection of misaligned turnouts in dark territory, and roadway worker protection

- Rail worker wayside safety is enhanced with special AVANTE ZONER-RW badges and tags that transmits its operation and communicating with RELAYER-CONTROLLER onboard of locomotive to all approaching trains within a 1000-3000 meters.

- Special train-based AVANTE RAIL-MONITOR that uses a combination of Doppler Radar, Infra-red and Optical (DRIRO) imaging technology with onboard display to provide additional ability to see beyond and in supplement to the train driver. This DRIRO based AVANTE RAIL-MONITOR also provides buzzer alerts for potential objects that are within the 3000 meters in front of the train.