Real-Time Alerts and Reporting of Exceptions

Real-Time Alerts and Reporting of Temperature and/or Humidity Exceptions are Some of the Critical Attributes of AVANTE Third Party Cold Chain Monitoring and Compliance Certification Services

Cold Chain Logistics (CCL) management and Hazard Analysis & Critical Control Point Monitoring and Compliance Certification Services for Pharmaceutical Products

| Example Temperature Excursion Handling of a Refrigerated Product(According to a draft medicinal cold chain guideline by PDA Cold chain working group, Nov. 03) | |

| Temperature Range | Time |

| <-20°C | Do not use |

| -20°C to 2°C | 2 days |

| 2 to 8°C | Until Expiration |

| 8 to 25°C | 6 days |

| 25 to 40°C | 2 days |

| > 40°C | Do not use |

In cold chain management, the ability to provide corrective action with perishable products that may be damaged either by excessive heat or freezing is much better than attribution of responsibility after damages.

AVANTE Cold Chain Transportation Management System achieves this objective with patented RFID technology and methods:

- Embed the ZONER-PBID inside the perishable goods and report the “real” temperature of the goods. Monitor in real-time the temperature and temperature distribution of the perishable goods placed in a reefer container or reefer truck.

- Report temperatures and/or humidity in real-time to the outside monitoring RELAYER-CTCR.

- Report alerts of any exceptions via GPS-GPRS-SATCOM equipped on RELAYER-CTCT to the AVANTE central web-based monitoring data center.

- Instant phone and web messages are sent automatically for any exceptions.

- Corrective actions may be executed directly by onsite staff or driver that also receives alerts on the RELAYER-CTCR screen, or by calling for action by the shippers or consignees.

- Responsible personnel including driver and loading staff are also monitored with personnel ZONER-SSID badges.

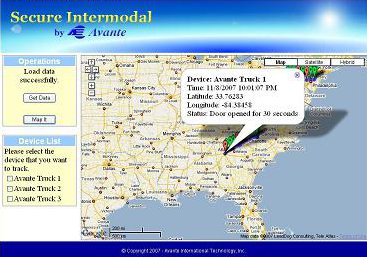

- Besides temperature and/or humidity excursion, any opening of the cold chain storage reefer container or reefer truck is noted and reported.

- In case of precious pharmaceuticals and drugs, the ability to monitor any unauthorized intrusion is critical. AVANTE Cold Chain Transportation Management System incorporates this capability by monitoring the ZONER tags inside the container.

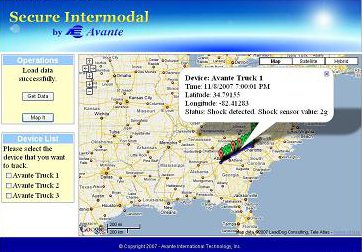

While most perishable goods are not particularly sensitive to shock and vibration, AVANTE Cold Chain Transportation Management System provides real-time shock monitoring for sensitive materials. Thus, the AVANTE Cold Train Transportation Management System is also applicable for animal transportation which may be sensitive to extended shock during travel.

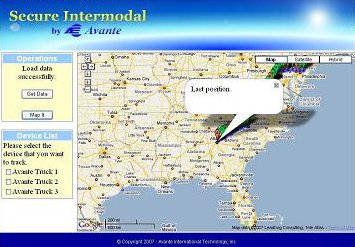

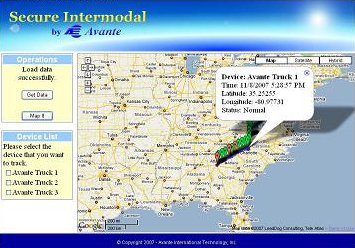

AVANTE Cold Chain Transportation Management System provides real-time location data to shippers or consignees via its web-based data center. Users can also identify the exact location and aerial view via “Google Earth”.

AVANTE Cold Chain Transportation Monitoring Solution and Services provides real-time location data to shippers or consignees via its web-based data center. Normal status of the cold chain reefer container or reefer truck is reported periodically. Exceptions are reported in real-time.

Benefits of AVANTE Third Party Cold Chain Logistics (CCL), Hazard Analysis & Critical Control Point Monitoring and Compliance Certification Services

AVANTE cold chain management solution represents a paradigm shift from accounting and attribution after spoilage and loss to preventive and corrective actions to safeguard products that may mean life or death whenever critical vaccines and medications are involved.

- Real-time alerts via phone/text messaging and real-time web-based reporting of any exceptions and suggestions for possible corrective actions by onsite drivers or staff.

- 24/7 end-to-end visibility of conditions and locations of valuable perishable goods via web-based data center with role-based access management.

Real-Time Cold-Chain Visibility includes:

- Monitoring during shipping and transportation.

- Fixed site storage conditions.

- True temperature detection by directly embedding sensors with the products rather than at the door.

- Temperature accuracy to 0.5°C at the content.

- Temperature distribution of the refrigerated goods with multiple ZONER tags.

- Optional shock data and exceptions in all three directions.

- Optional humidity reports.

- Documents whenever, wherever, and for how long the reefer trailer or reefer container is open.

- Locate the driver at all times.

- Determination of the reefer conditions and possible maintenance and repair requirements.

- Real-time location of the refrigerated container or trailer.

- Intrusion detection and real-time alerts of the refrigerated container and trailer box.

| AVANTE Third Party Monitoring and Compliance Certification Services for Automated End-to-End Hazard Analysis & Critical Control Points (HACCP) and/or Cold Chain Logistics (CCL) Management | |

| COLD CHAIN LOGISTICS (CCL) Hazard Analysis & Critical Control Point (HACCP) Requirement | Automated AVANTE Third Party Monitoring & Certification Services |

Critical Control Point (CCP) #1 (Start):

| AVANTE Compliance Monitoring & Certification:

|

Critical Control Point (CCP) #2 (Storage):

| AVANTE Compliance Monitoring & Certification:

|

Critical Control Point (CCP) #3 (Transport):

| AVANTE Compliance Monitoring & Certification:

|

Critical Control Point (CCP) #4 (Storage):

| AVANTE Compliance Monitoring & Certification:

|