COLD CHAIN LOGISTICS WITH REAL-TIME ALERTS OF TEMPERATURE AND/OR MOISTURE EXCEPTIONS WITHIN A REFRIGERATED WAREHOUSE COLD STORAGE FACILITY

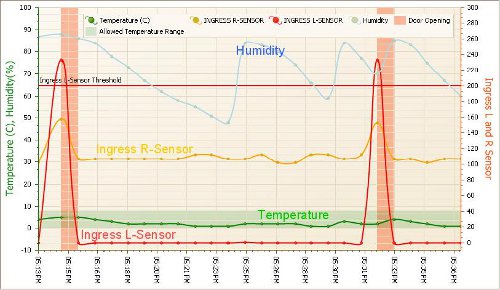

While refrigerated container transportation in cold chain logistics is the most vulnerable phase of end-to-end cold chain safety and security monitoring, conditions of the refrigerated warehouse distribution center (DC) and other cold storage facilities are also important parts of cold chain logistics. Traditional data loggers record temperature and/or humidity and report after the fact. While “post mortem” data is useful for attributing responsibility in case of failure, it does not prevent potential productivity lapses or loss of food-goods and/or spoilage of vaccines and pharmaceutical supplies.

Instead of the traditional “first-in-first-out” (FIFO) approach, AVANTE’s cold chain monitoring solution maintains end-to-end visibility of the products being managed which enables a “first-expire-first-out” (FEFO) approach to ensure optimal cold chain transportation

PanaSec-AVANTE has developed and made available monitoring services to the cold chain logistics industry based on the following goals:

- “FEFO” vs. “FIFO” with Verifiable Temperature-Humidity History ON-and-OF the Products

- Real-Time Alerts of Exceptions for Corrective Actions

- End-to-End Verifiable Certification

PanaSec-AVANTE is proud to provide end-to-end monitoring services with innovations enabled with the US 7,342,497; 7,423,535; 7,319,397; 7,513,425; 6,883,710; 7,036,729; 6,703,935; 6,696,954; 6,943,688; 6,665,543; and other pending US patents.

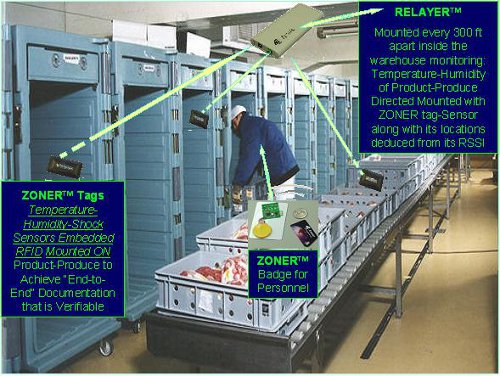

The following are illustrations of the configuration for ZONER sensor devices for monitoring temperature, humidity, shock, intrusion, light and sound. ZONER badges for personnel involved in the cold chain logistics and a monitoring RELAYER reporting the conditions periodically and exceptions in real-time are also depicted