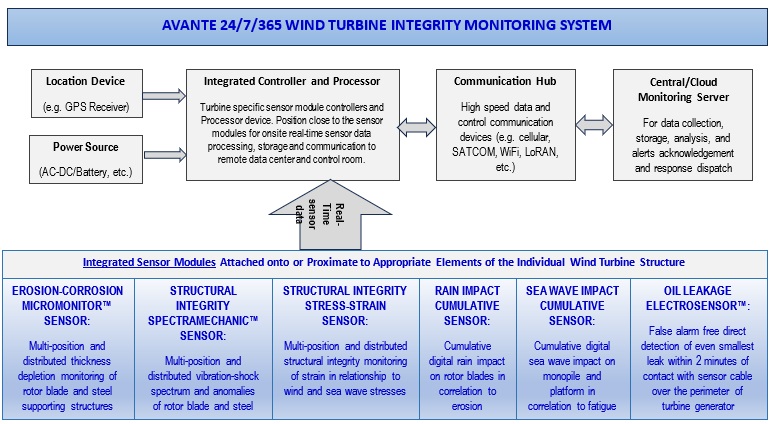

Online monitoring of erosion and corrosion damages and real-time alerts for exceptions in fatigue and mechanical damage induced stresses signaling potential hazardous and provide timely maintenance and prevent catastrophic failures:

- Rotor blade leading edge thickness depletion monitoring coupling with rain intensity cumulative effects over time allowed predictive maintenance.

- Monopile and other thickness depletion monitoring over time from corrosion provides predictive maintenance.

- Wind and wave intensity and stress-strain and vibration spectrum monitoring on the rotor blades and supporting structures for exception correlations and alerts.

AVANTE patent-pending Wind Turbine Integrity Monitoring System incorporates quantitative sensor modules that can be cost effectively and non-intrusively installed on the inside surfaces of the leading edge of the rotor blades and along the supporting structures to monitor all the potential hazards that can damage the wind turbine. AVANTE Small Leak Detection System provides a supplementary digital and real-time alerts for any lubricant and transmission fluid leaks that is detrimental to the proper functioning and potential fire-hazards.

AVANTE Holistic Wind Turbine Integrity Monitoring System (WTIMS) for Rotor Blade and Steel Support Structures Visibility and Management:

- Online monitoring system for quantitative measurements of the erosion and corrosion that weakens the wind turbine.

- Online and real-time monitoring of the vibrational spectral responses and excessive strain for exception alerts for timely response.

- Redundant communication channels for wireless and/or wired communications and controls of the data collections and reporting requirements.

- AI based analysis of the mechanical spectral data over time to provide exceptions reporting.

- 24/7/365 digitized monitoring of erosion, corrosion, rain impact, sea wave impact, exceptions in vibrations and strain responses, oil leakage from lubricant and transmission fluids.

Comprehensive integrated erosion and corrosion rate and status of the rotor blades and wind turbine supporting structure provides quantitative and objective assessment of the wind turbine integrity. Coupling with the external stresses that causes the erosion of the rotor blades provide the capability of rate of degradation for predictive maintenance. Online and real-time monitoring of the mechanical structural responses to the rotor blades and the supporting structures separately can help to provides exceptions in spectral behavior caused by sudden onset of stress concentration or fatigue.

AVANTE MICROMONITOR™ Erosion and Corrosion Rate Monitoring System

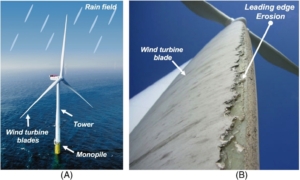

Leading edge effect (LEE) of the wind turbine blade (WTB) erosion is one of the main causes of wind turbine mechanical failure and slow degradation of the wind energy conversion efficiency. It is one of the major costs in the operation for inspection, repair and maintenance. AVANTE MICROMONITOR erosion rate monitoring system can provide predictive maintenance scheduling without onsite inspection.

Changes over time for the structural vibration spectrum signature of both the turbine blade and support steel structures are important indicator of substantial degradation. Any substantial fractural of any of the structures produces exception in the vibration signature should alert the operational team of potential dangers requiring immediate attention and inspection.

AVANTE Rain Impact Cumulative Sensor System

Changes over time for the structural vibration spectrum signature of both the turbine blade and support steel structures are important indicator of substantial degradation. Any substantial fractural of any of the structures produces exception in the vibration signature should alert the operational team of potential dangers requiring immediate attention and inspection.

AVANTE Cumulative Wind-Wave Stress-Strain Monitoring System

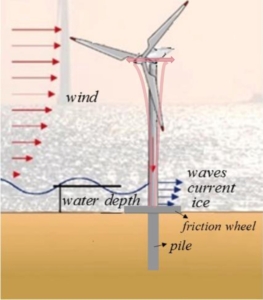

Wind turbine structure onshore subjects to wind gusts, storm and hurricane that may cause substantial wind loading stress on the tall structure with expansive turbine blades. Offshore turbine structure subjects to additional ocean wave loading at different depth. Wind and sea wave stress causes the swing or tilt of the supporting tower and the twisting and bending of the rotor blade.

AVANTE Small Oil Leakage ELECTROSENSOR™ Monitoring System

Leakage of lubricant and transmission fluid can affect the wind turbine efficiency and potential mechanical failure. Excessive leakage can also cause contamination around the turbine and also known to cause fire hazard and total system damage. AVANTE Leakage ELECTROSENSOR ™ monitoring system is engineered to provide false alarm free direct detection of even smallest leak within 10 minutes of contact with sensor cable over the perimeter of turbine generator.